In metalworking, coolants play a crucial role by providing cooling and lubrication to ensure workpiece surface precision and extend tool life. In the industry, coolants are generally classified into oil-based and water-based types. Among them, water-based coolants (such as cutting fluids and grinding fluids) require careful management; poor handling can easily lead to undesirable results. Operators must pay special attention during use. Below are basic guidelines for managing metalworking fluids for reference:

Q: What is the proper concentration for water-based metalworking fluids?

A: The concentration varies depending on the machining conditions. Ratios should follow the technical data provided by the supplier. Insufficient concentration can directly affect tank life, tool life, and surface accuracy. Excessive concentration increases costs and reduces defoaming performance. Proper concentration management ensures efficiency and reduces potential issues.

Q: What should I pay attention to when diluting the concentrate?

A: When preparing new coolant, pay attention to the oil-water mixing sequence. Always add the concentrate to the water, not the other way around, to ensure proper emulsification and stability, avoiding oil-water separation. Operators may also use commercially available oil-water mixers.

Water quality greatly affects coolant stability (>90% of impact comes from dilution water). Hard water can destabilize the emulsion. Tap water is generally suitable, but for maximum fluid life and effectiveness, using deionized or RO-purified water is recommended.

Q: How should I top up the coolant?

A: During machining, the fluid level in the machine tank decreases due to workpiece removal, chips, and evaporation. Fresh fluid should be added as needed. Since evaporation mainly involves water, the concentration of the new fluid is usually lower than the recommended level. For example, for a 5% tank, the new fluid is often around 1–2%. Consult your supplier for specific guidance. Top-up frequency depends on machining conditions, ranging from daily to weekly.

Q: What is the difference between refractive index and concentration?

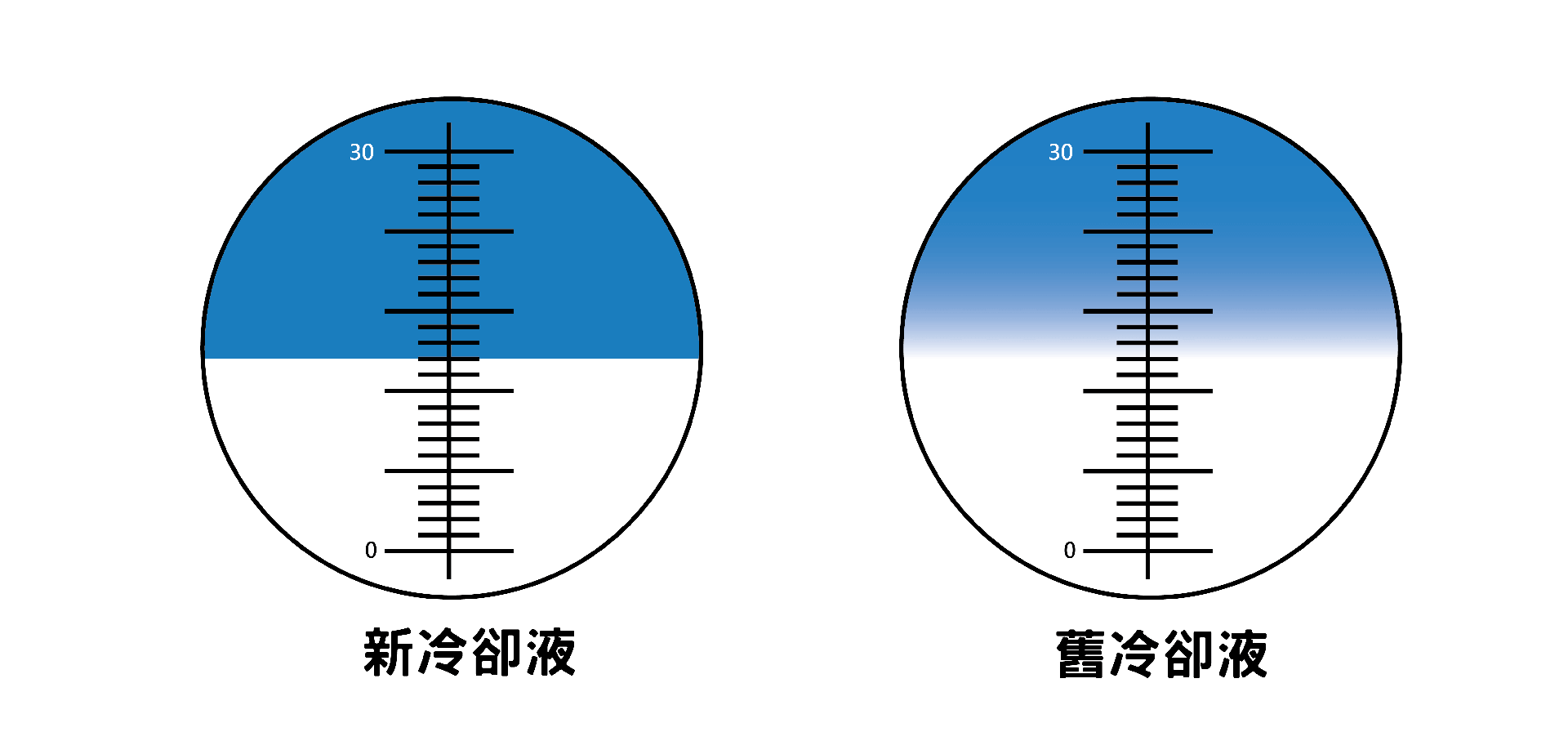

A: Refractive index is used to determine coolant concentration. Different products may have different coefficients, usually provided in the product manual.

Concentration = Refractive Index × Refractometer Reading

Many fluids have a coefficient of 1, so the refractometer reading equals the fluid concentration. Operators should check tank concentration daily to maintain proper levels.

(Illustration 1: Refractometer Reading Example)

Q: Why does my tank smell bad?

A: Odor is caused by bacterial and fungal growth. Bacteria react with coolant and floating oils, destroying lubricants and rust inhibitors, releasing sulfur compounds (H2S) that produce the “rotten egg” smell. Acidic substances and salts may also lower pH and reduce rust protection. To prevent this:

- Maintain concentration within recommended range.

- Keep the work environment clean.

- Avoid introducing contaminants into the tank.

- Use an effective filtration system and remove chips regularly.

- Clean the tank and machine thoroughly when changing fluid.

Q: How does floating oil affect my coolant tank?

A: Floating oil usually comes from machine lubricants (e.g., slideway or spindle oil). Excessive floating oil can cause emulsion discoloration, separation, foaming, and oil mist. Oil mist can damage sensitive electronics or clog filters. Long-term coverage blocks air exposure, promoting anaerobic bacteria and lowering concentration, potentially causing skin irritation. A good oil-water separation system can mitigate these issues. Commercial solutions include disc-type, belt-type, coalescing, or centrifugal separators. Oil mist collectors are also available to reduce health and equipment risks.

Q: How do metal residues affect my coolant tank?

A: Metal residues generated during machining are typically harder than the original material. If not properly filtered, they can re-enter the coolant circulation, reducing tool life and surface finish quality. Small residues take hours to settle, accumulating in stagnant areas (e.g., tank corners), creating a breeding ground for anaerobic bacteria. Regular removal of metal residues is essential. Pneumatic or centrifugal systems are available to effectively remove residues, ensuring coolant quality and stability.

Metalworking fluids account for only 1–2% of consumable costs but can directly and indirectly affect over 95% of machining and maintenance costs. Therefore, proper selection and management of coolants are critical. Correct use of cutting fluids is an essential factor in improving overall production efficiency and profitability.