In 2013, director Chi Po-lin’s documentary “Beyond Beauty: Taiwan from Above” revealed Taiwan’s landscape through aerial photography for the first time. The film brought the issue of river pollution into the spotlight. Five years later, Taiwan’s Environmental Protection Administration (EPA) released its annual Environmental Protection Statistics Report, showing that among Taiwan’s 2,933.9 kilometers of major rivers, 868 kilometers still recorded an RPI (River Pollution Index) above 2.0. The findings highlight that nearly 30% of rivers remain polluted.

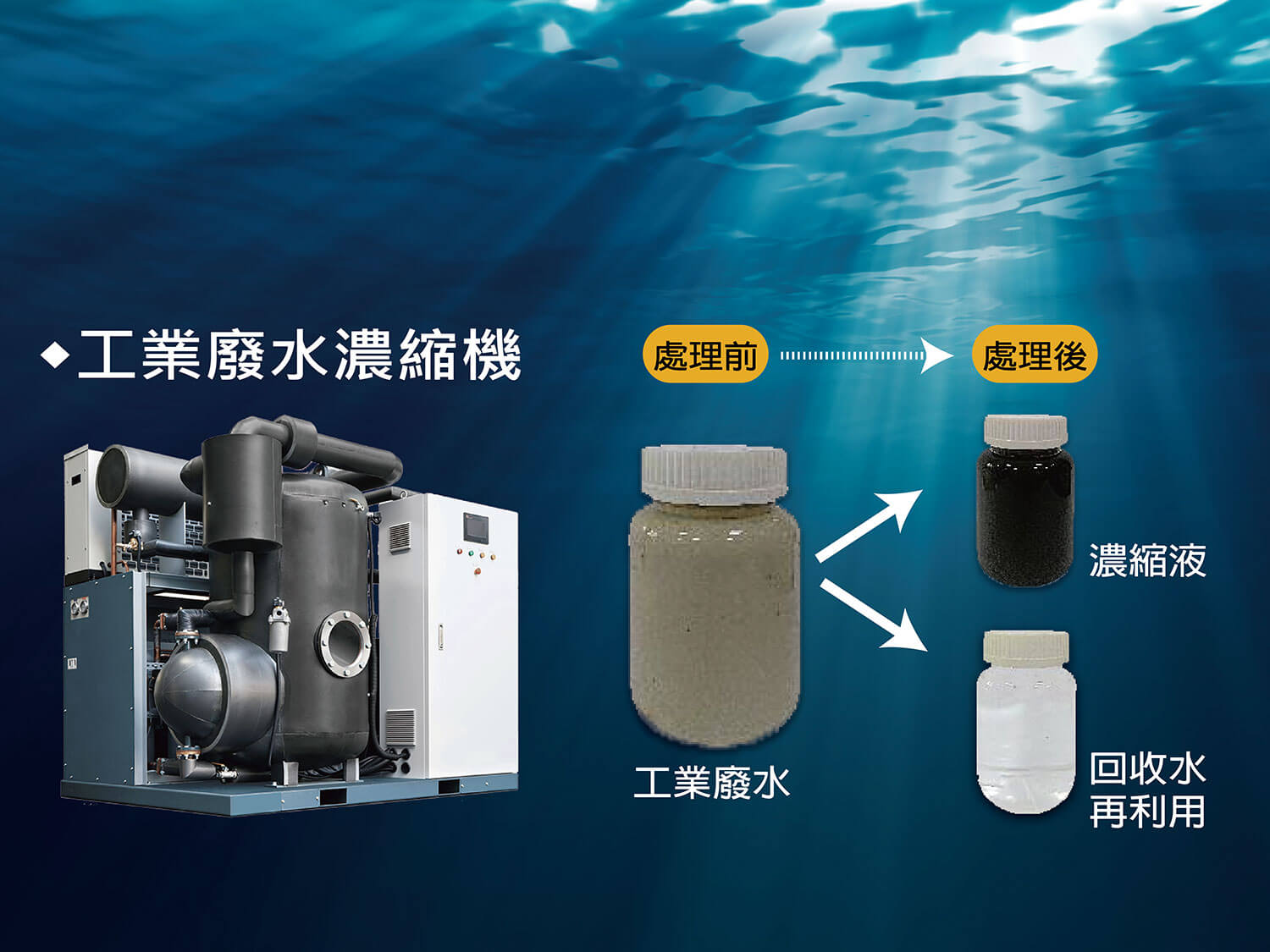

To tackle the persistent issue of industrial wastewater pollution, Taiwan Fimitech Co., LTD. has launched the “Industrial Wastewater Treatment Machine” equipped with a high-efficiency scroll-type heat pump compressor. Unlike traditional chemical treatment, this machine applies innovative vacuum evaporation-condensation technology, reducing wastewater volume to just 1/20 of its original amount. The remaining recycled water can be reused, achieving a green goal of zero discharge and zero pollution—making it a savior for industries facing wastewater challenges.

Water, soil, air, and sunlight are essential for sustaining life, yet in recent years, pollution has increasingly threatened our living environment. CEO David Yeh of Taiwan Fimitech recalls his father telling him that Taiwan was once truly a “beautiful island,” where even ditches in front of homes were crystal-clear, with fish and shrimp swimming freely. Sadly, today’s rivers not only lack aquatic life but also emit foul odors due to untreated wastewater. Fimitech was founded with the mission of becoming a driving force for green manufacturing, introducing eco-friendly lubricants from the globally renowned German BECHEM Group, and moving towards goals of safe production, zero pollution, and zero defects.

With over 30 years of history, Taiwan Fimitech is now the leading supplier of high-grade metalworking oils in Taiwan, providing eco-friendly and safe products that have earned industry-wide recognition. However, seeing factories discharge untreated wastewater into rivers deeply concerns CEO Yeh. “We should not sacrifice our environment for economic development,” he emphasized. “That’s why we launched the Industrial Wastewater Treatment Machine—to truly address the issue.”

The machine represents a revolutionary innovation, replacing traditional incineration methods and eliminating the risk of air pollution. By applying vacuum evaporation-condensation technology, wastewater is distilled in a vacuum tank at low boiling points between 40°C and 60°C. The vapor then condenses into clean water, reducing 20 barrels of wastewater into just one, while the other 19 barrels are recycled for reuse.

According to CEO Yeh, this wastewater treatment machine is truly a game-changer. The current cost of certified wastewater treatment is around NT$10–14 per liter, placing a heavy burden on businesses. Depending on customer needs, this concentrator can process 200–2,000 liters per day. Thanks to the high-efficiency scroll-type heat pump compressor, energy consumption is drastically reduced, with treatment costs falling below NT$1 per liter. This not only helps businesses cut expenses but also achieves the green goal of zero discharge and zero pollution, contributing to a cleaner environment for Taiwan.